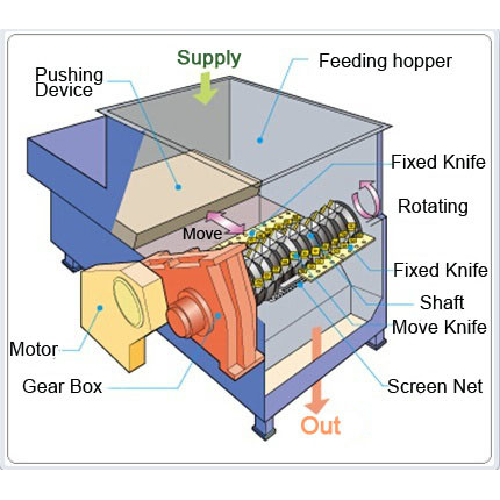

- Operating Principle: Single shaft shredders consist of a single rotor with

blades or hammers that rotate at high speeds. The material to be shredded is fed into the

machine's hopper or loading chamber, and the rotating blades tear, cut, or crush the

material into smaller pieces.

- Materials Processed: Single shaft shredders are versatile and can handle a

wide range of materials, including plastics, wood, rubber, paper, cardboard, metal,

electronic waste (e-waste), and more. The specific design and configuration of the shredder

may vary depending on the material being processed.

- Applications: These shredders are used in various industries, including

recycling, waste management, manufacturing, and more. Common applications include reducing

the size of plastic bottles, automotive parts, tires, electronic components, and industrial

waste.

- Size Reduction:The primary purpose of a single shaft shredder is to reduce

the size of materials, making them easier to transport, store, or further process. The size

of the shredded output can be controlled by adjusting the shredder's screen or blade

configuration.

- Maintenance: Single shaft shredders are equipped with safety features to

protect operators from hazards, such as emergency stop buttons, safety interlocks, and

protective barriers.

- Safety Features: Regular maintenance is essential to ensure the efficient

operation of a single shaft shredder. This includes blade sharpening or replacement,

lubrication, and inspection of wear parts.

- Advantages: Single shaft shredders are known for their robustness,

simplicity, and versatility. They can handle a wide range of materials and are relatively

easy to operate and maintain.

- Disadvantages: While single shaft shredders are effective for many

applications, they may not be suitable for extremely high-volume or specialized tasks that

require more specialized equipment. In such cases, dual shaft shredders or other shredder

types might be more appropriate.

- Environmental Benefits: Using single shaft shredders in recycling processes

can help reduce landfill waste, conserve resources, and lower energy consumption compared to

manufacturing products from raw materials.

- Customization: Single shaft shredders are available in various sizes and

configurations to meet specific application requirements. Manufacturers often offer

customization options to match the needs of different industries and materials.

In summary, a single shaft shredder is a versatile industrial machine used for reducing the size

of various materials, and it plays a crucial role in recycling and waste reduction processes

across different industries.