The smelting process involves several stages, which may vary depending on the specific metal

being produced. Here is a general overview of the steps involved in base metal smelting:

- Preparation: The first step is the preparation of the ore, which involves

crushing and grinding it into smaller particles. This process increases the surface area of

the ore and facilitates the release of the metal-bearing minerals.

- Roasting: In some cases, the ore may undergo a roasting process before

smelting. Roasting involves heating the ore in the presence of oxygen to eliminate volatile

impurities, such as sulfur, arsenic, and carbon. It also converts certain metal compounds

into more favourable forms for subsequent processing.

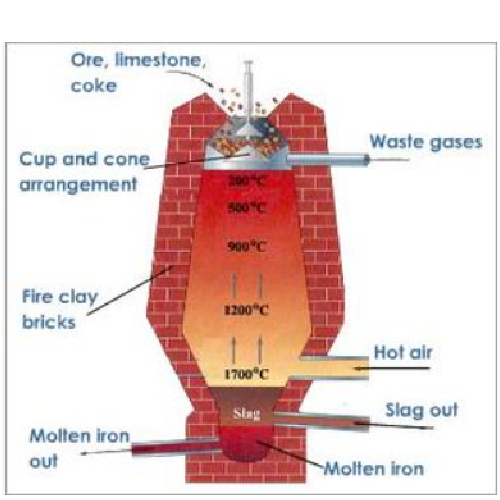

- Smelting: Smelting is the main process where the ore is heated in a furnace

along with a

reducing agent (often carbon) to remove oxygen and other impurities, resulting in the

formation of a molten metal. The specific temperature and conditions vary depending on the

metal being smelted. During smelting, various reactions occur, including the reduction of

metal oxides and the formation of slag (a by-product that contains impurities).

- Refining: After smelting, further refining processes may be necessary to

achieve the desired purity of the base metal. Refining techniques can involve additional

heating, chemical processes, or electrolysis. These methods help remove remaining impurities

and separate the base metal from other elements.

- Casting: Once the metal has been refined, it is usually cast into ingots,

bars, or other desired shapes for ease of transportation and further processing.

It's worth noting that the specific smelting processes and techniques can vary depending

on the type of base metal, the characteristics of the ore, and the desired final

product. Environmental considerations are also crucial in base metal smelting to ensure

the proper treatment and disposal of byproducts, such as slag and emissions.