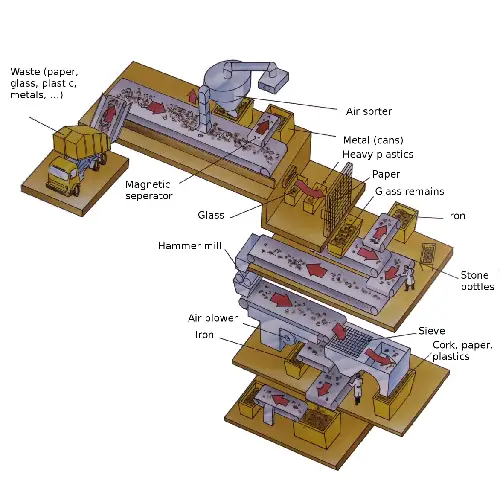

Here's how a typical MRF operates:

- Collection: Waste materials are collected from various sources, including

households, businesses, and public recycling bins. This waste is often mixed and unsorted,

containing various recyclables, such as paper, cardboard, plastics, glass, and metals, along

with non-recyclable waste.

- Pre-sorting: Before the waste enters the MRF, some preliminary sorting may

occur. This can include manual sorting at the collection point or using equipment like

magnets to remove ferrous metals.

- Conveyor Belt System: Once inside the MRF, the mixed waste is typically

placed on a conveyor belt system, where it begins its journey through the facility.

- Primary Sorting: In the initial sorting process, workers and automated

machinery (like screens and conveyor belts with sensors) are used to separate materials by

type. For example, paper and cardboard are separated from plastics, metals, and glass.

- Secondary Sorting: After the primary sorting, materials are often further

sorted to improve the quality of the recyclables. This may involve additional conveyor

belts, manual sorting, or advanced sorting equipment, like optical sorters that use cameras

and software to identify and separate materials.

- Baling and Compaction: Once the materials are sorted, they are compacted

into bales or other suitable forms for efficient storage and transportation. Each material

type (e.g., cardboard, aluminum cans, plastic bottles) is typically baled separately.

- Storage and Transportation: The baled materials are stored at the MRF until

they are ready to be transported to manufacturers or other facilities that will process them

into new products.

- Marketing and Sale:The MRF sells the sorted and baled materials to

recycling companies or manufacturers that use these materials as feedstock for making new

products.

Materials Recovery Facilities play a crucial role in the recycling process, helping to divert

recyclable materials from landfills and conserve natural resources. They also contribute to

reducing the environmental impact of waste disposal and promoting sustainability.

The efficiency and capabilities of MRFs can vary widely depending on their technology, automation

level, and the types of materials they handle. Advanced MRFs may incorporate robotics and

artificial intelligence to improve sorting accuracy and efficiency.