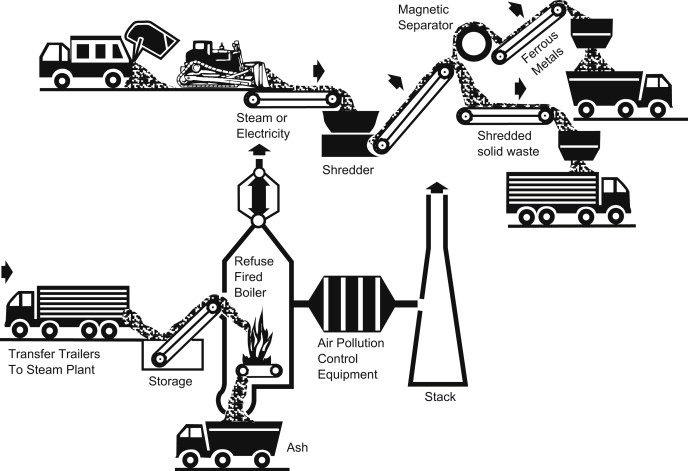

Here's how an RDF shredder typically works:

- Material Collection: Waste materials that cannot be recycled or composted are

collected from various sources, such as municipal solid waste (MSW) facilities or industrial

waste streams.

- Sorting and Pre-processing: Before shredding, the waste is usually sorted to

remove any hazardous or non-combustible materials. This can be done manually or using automated

sorting systems.

- Shredding: The RDF shredder is used to reduce the size of the remaining waste

materials into smaller, more manageable pieces. The shredding process involves powerful rotating

blades or hammers that tear the waste into smaller chunks.

- Screening and Separation: After shredding, the material may go through a

screening process to separate fine particles and contaminants from the desired RDF material.

This helps ensure the quality and consistency of the RDF.

- Quality Control: Quality control measures are often in place to ensure that the

RDF produced meets specific standards for calorific value, moisture content, and other

parameters.

- Storage: The shredded and screened RDF is typically stored in bunkers or silos

until it is ready for use.

- Transport: Once the RDF is ready, it can be transported to facilities where it

will be burned or gasified to generate heat or electricity.

RDF shredders come in various sizes and capacities, depending on the volume of waste to be processed

and the specific requirements of the facility. These machines are designed to handle a wide range of

waste materials and are an important component of waste-to-energy systems that aim to reduce

landfill disposal and harness energy from waste materials.

It's worth noting that the use of RDF and RDF shredders is subject to environmental regulations and

standards to ensure that the combustion of RDF produces minimal emissions and is conducted in an

environmentally responsible manner.